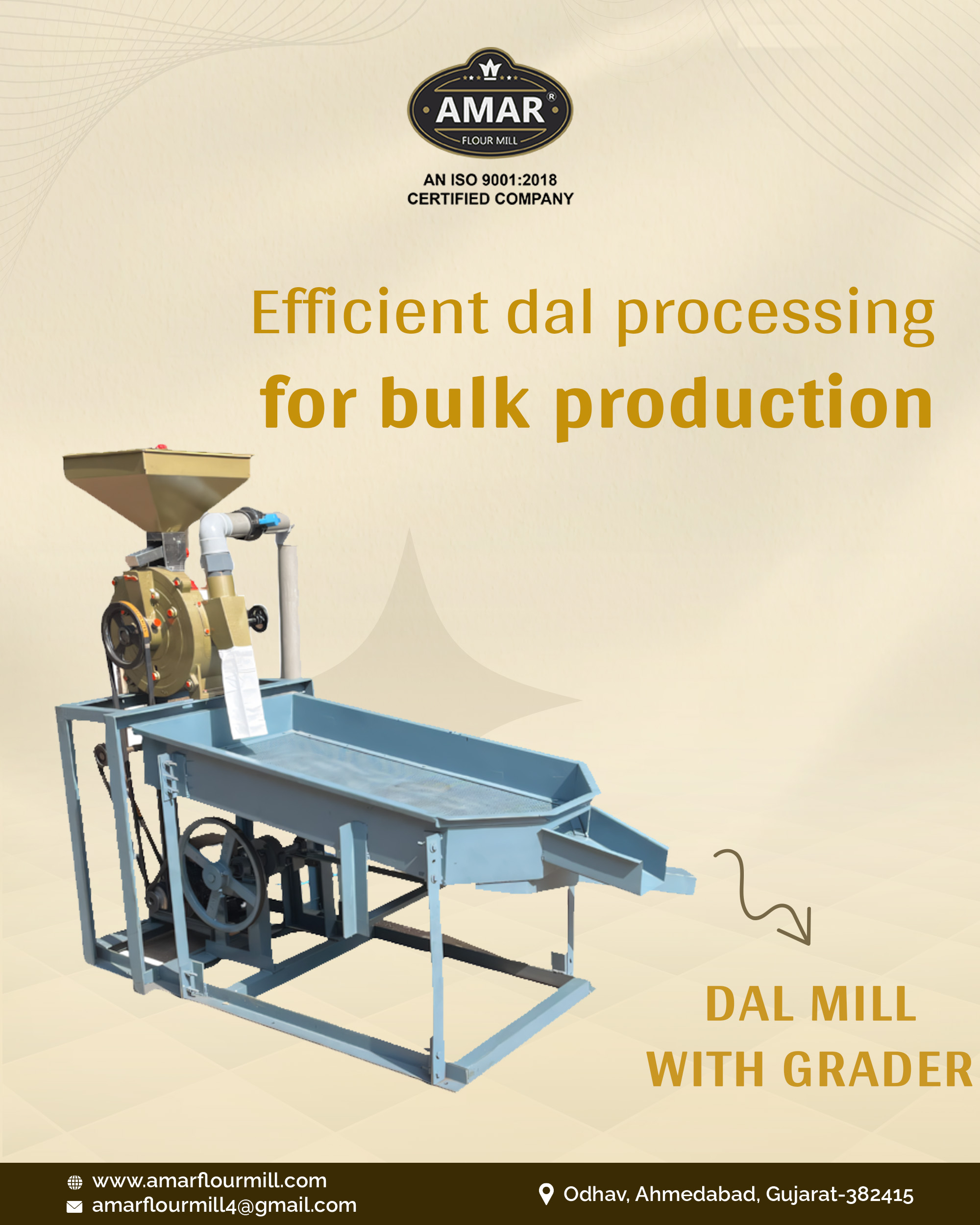

Amar Industries is known for manufacturing various agricultural and industrial machines, including Dal Mill with Grader. A Dal Mill with Grader typically consists of machines designed for processing pulses (dal) and separating them based on size, shape, and quality. Here's a breakdown of its components and functionality: Dal Mill with Grader: Dal Mill (Pulse Mill): Function: The main purpose of the Dal Mill is to process pulses by cleaning, de-husking, and splitting them. Components: De-husking unit: Removes the husk from the pulses. Splitting unit: Splits the pulses into smaller pieces. Cleaning unit: Removes impurities like dust, stones, and other foreign matter from pulses before they are processed. Grader: Function: A grader is used to separate the processed dal based on size and quality. It typically works by sorting pulses into different grades, ensuring only high-quality pulses are packaged and sold. Components: Vibration system: Helps in the uniform distribution and sorting of pulses. Screens/mesh: Used for grading the pulses into different sizes. Motor and gearbox: Ensures smooth operation of the grading system.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry